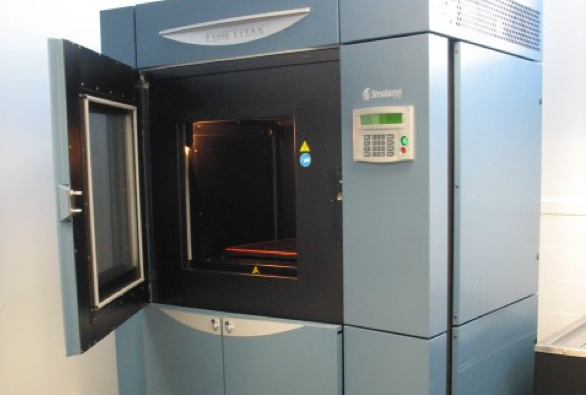

Formlab uses FDM (Fused Deposition Modeling) technology developed by Stratasys. This technology builds a succession of thin layers of material, one over the other, at appropriate locations to produce the desired object.

The digital printer consists of a work surface which moves vertically (Z axis) and an extrusion nozzle which moves horizontally (X and Y axes). An ABS filament is extruded through the nozzle at a temperature just above its melting point and is deposited to build the model layer, hardening immediately on contact with the previous layer.

FDM TITAN

Once a layer is complete, the table moves down by a value determined by the model resolution. The geometry under construction retains its shape through the use of support material which fills the empty spaces in the model. Once the modeling is complete, the part is placed in a bath to remove the soluble support from the model.